A die in production is a specialized device used to form or reduce materials into particular bureaucracy or dimensions. Dies are vital additives in methods like stamping extrusion forging and forming metals plastics and composites. They allow mass production of elaborate elements with consistency and accuracy enhancing efficiency in production operations.

Normally made from difficult and sturdy materials like steel carbide or diamond,what is a die in manufacturing dies are engineered to withstand high forces and extended use. They may be meticulously designed to satisfy particular necessities ensuring uniformity in the produced elements.

Dies can vary widely in complexity from easy dies appearing unmarried operations to compound or progressive dies able to multiple operations in a single stroke.The design and fabrication of dies contain intricate techniques such as forging casting machining and electrical discharge machining .

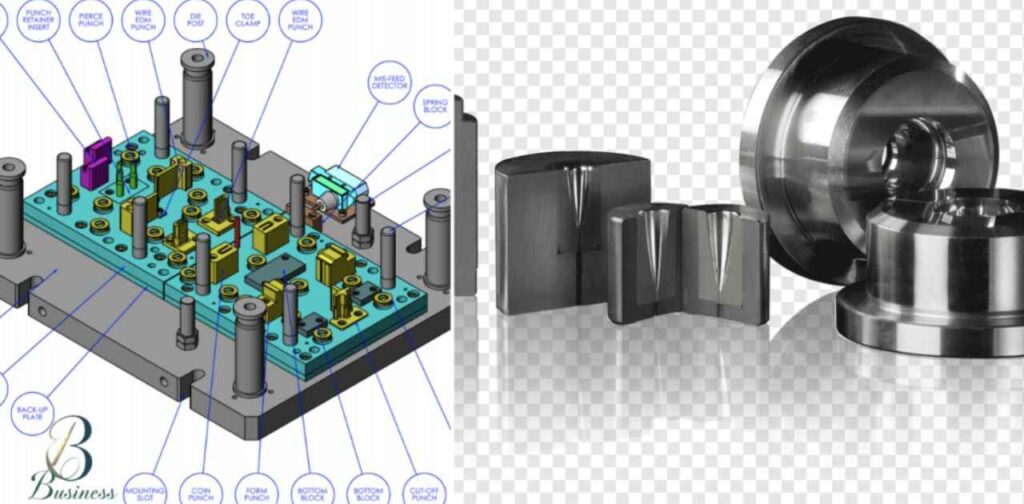

The Various Parts of a Die Set

A die set contains several important components that paint collectively to form or reduce substances with precision. These additives consist of the punch plate die block clean punch pierce pinch shank dowel pin pierce punch pilot stripper plate and retainer. Each component serves a particular function from guiding and securing the die to controlling the forming or reducing manner.

Guide pins and bushings make certain proper alignment and motion of the upper and lower die shoes allowing for easy operation. Heel plates and blocks take in aspect thrust generated for the duration of forming or slicing retaining alignment and stability. Screws keys and dowels secure the additives in place facilitating efficient operation and stopping misalignment.

Stress pads stripper pads and draw pads exert force and manipulate the fabric for the duration of the forming or reducing system. These pads assist in gaining desired shapes and dimensions at the same time as minimizing defects. Springs provide the vital force to preserve form or strip the cloth contributing to the overall functionality and overall performance of the die set.

Read more:How To Start A Freeze Dried Candy Business

Types of Stamping Die Manufacturing Techniques

Stamping die production encompasses numerous strategies tailored to particular production requirements. Six primary styles of stamping die production techniques encompass easy die combination die compound die innovative die switch die and a couple of die. .Styles of Stamping Die manufacturing strategies

Easy Die

A smooth die is a truthful tool used for basic stamping obligations. It performs a single operation with one stroke making it easy and efficient. Easy dies are usually hired for tasks like piercing blanking or forming simple shapes. They offer ease of use and are perfect for small scale production or prototyping.

Compound Die

A compound die is a flexible tool used for multiple operations in an unmarried stroke. It helps the simultaneous slicing bending or forming of complex parts. Compound dies are perfect for generating complex additives with efficiency and precision. They streamline manufacturing approaches and are usually utilized in mass manufacturing environments.

Revolutionary Die

A revolutionary die is a modern tool that transforms conventional production procedures. It integrates advanced technologies like automation AI or additive production to decorate efficiency and productivity. By revolutionizing traditional die making strategies those dies allow quicker production cycles and superior exceptional control.

Combination Die

A combination die is a multifunctional tool capable of performing multiple operations in one stroke. It integrates forming and cutting processes streamlining production and boosting efficiency. Combination dies are ideal for tasks such as combined deep drawing and blanking or bending and piercing.

Materials of Die Manufacturing

Materials utilized in die production play a critical function in determining the dies sturdiness performance and price effectiveness. Usually utilized substances encompass diverse types of steels both ferrous and non-ferrous in addition to non steel materials.

Carbon metallic is a popular preference for die manufacturing because of its slight value and accurate machinability. It generally contains manganese carbon sulfur phosphorus and silicon presenting ok power and wear resistance.

Specialized steels like tungsten oil hardening metal and high alloy oil hardening steel are employed for dies requiring more suitable hardness and put on resistance. Those steels contain alloying factors together with tungsten chromium nickel and vanadium to impart advanced mechanical residences.

Materials for Producing Low-Cost Die

In scenarios in which value performance is paramount, die makers regularly explore opportunity substances to supply low price dies. Those materials encompass both metal and non steel options each providing awesome blessings and boundaries.

Non ferrous substances like Cerrobend and Kirksite are preferred for their distinctly low fee and simplicity of machining. Whilst these materials might not fit the durability of conventional steels they provide sufficient power for positive programs at a decreased cost.

Non steel materials which include Bakelite plastics Masonite and numerous woods also are applied in die production to lessen charges in addition. These materials are appropriate for much less annoying programs and may be processed via stretch-forming techniques to create dies at a fraction of the price of metal dies.

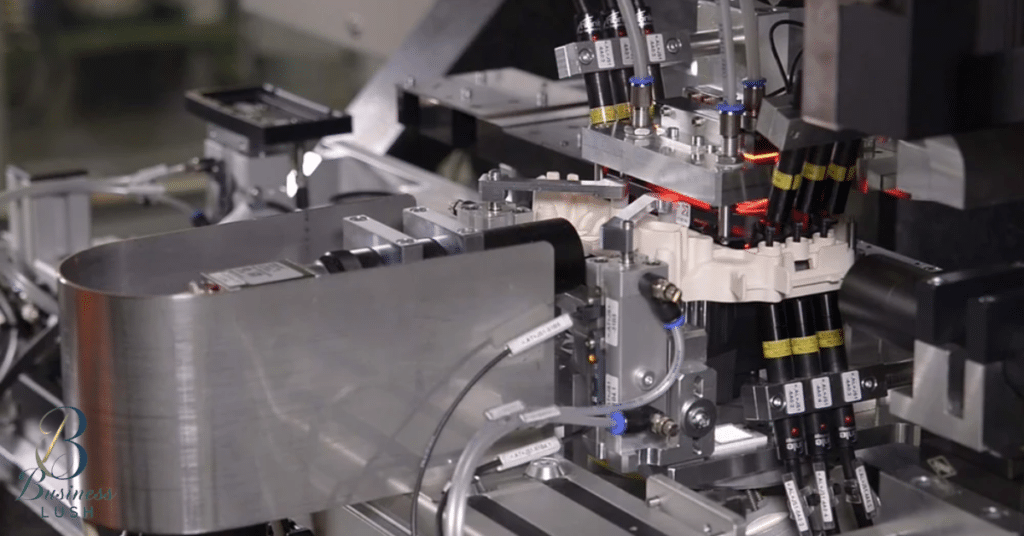

Die Manufacturing Process

The die manufacturing technique involves numerous stages from layout to fabrication to create specific gear for shaping or cutting materials. The technique starts with designing the die using a pc aided design software program. Designers create designated 2nd and three D models of the die specifying dimensions tolerances and capabilities.

As soon as the design is finalized a prototype of the die is created to check its capability and overall performance. Prototyping can also contain machining a scaled down version of the die to validate its design and capability.Primarily based on the die Is requirements appropriate substances are decided on for fabrication. Commonplace substances include diverse grades of metal carbide or different specialized alloys recognised for his or her hardness wear resistance and machinability.

The chosen cloth is machined using precision equipment and techniques to form it into the favored form of the die. Machining tactics may additionally consist of milling drilling turning grinding and electrical discharge machining (EDM) to attain tricky shapes and tight tolerances.After machining the die undergoes warmth remedy approaches like annealing hardening tempering or floor remedy to decorate its mechanical properties inclusive of hardness longevity and put on resistance.

Frequently Asked Questions

What materials are usually used in die manufacturing?

Common substances consist of metallic carbide and specialized alloys for durability and put on resistance.

What are the primary variations among a simple die and a compound die?

A simple die performs one operation in one stroke while a compound die can perform a couple of operations concurrently.

How do I pick out the proper form of stamping die for my undertaking?

Bear in mind factors like production extent component complexity and required operations to decide the maximum suitable die kind.

What preservation is required for stamping dies?

Regular protection which includes cleansing lubrication and sharpening enables certain premiere performance and longevity.

Can non-metallic substances be utilized in die manufacturing?

Yes materials like plastics Bakelite and timber can be applied for precise die applications specifically for value effective answers.

What is the everyday lead time for manufacturing a stamping die?

Lead instances vary primarily based on complexity and workload It usually tiers from weeks to months depending on elements like design fabric availability and production scheduling.

Conclusion

Die production is a multifaceted process vital to various industries from automotive to electronics. The meticulous layout fabrication and assembly of dies make certain the efficient production of precision components contributing to the general success of manufacturing operations. With improvements in substances technology and techniques die makers continue to innovate striving for higher performance accuracy and fee effectiveness in die manufacturing.

The numerous styles of stamping die manufacturing techniques provide tailor made answers to meet specific production wishes for easy or complex parts. Every technique brings its advantages and boundaries empowering manufacturers to optimize their strategies for stronger productivity and niceness. With the aid of knowing the differences among die types and selecting the maximum appropriate method, manufacturers can reap optimum outcomes of their stamping operations.

The selection of materials in die manufacturing is essential influencing the die is performance longevity and price. While traditional steels offer durability and strength non metal substances present price effective options for positive programs. Via leveraging a combination of materials and techniques die makers can meet the various demands of modern day manufacturing at the same time as using innovation and efficiency within the industry.

Meet Brook, our business blog guru. They turn business jargon into easy-to-read stories that captivate and inform. Dive into our blog and let Brook guide you through the corporate world with clarity and style.